Glove Standards and Cut Ratings

What is a Cut Rated or Cut Resistant Glove?

A Cut Rated or Cut Resistant Glove is a Glove that meets at least one of two rating standards. The EN388 Standard or the ANSI Standard. The EN388 Standard is a European Standard used throughout the world. The ANSI Standard is the Standard used only in America. Both Standards are measured differently and are used to determine the resistance of a material, such as a glove.

Cut Resistant Gloves are Gloves that are resistant to cuts, punctures, abrasion and tears. The Cut Rating of a glove determines how resistant to cuts the gloves are. In Australia and New Zealand we use the AS/NZS 2161 Glove Standards which are replicated from the EN388 Standard.

For your benefit The Glove Company have created an easy to understand Glove Standards Rating Chart below.

EN388 Mechanical Ratings Diagram, Table and Safe Usage

The higher the number the stronger the gloves resistance to that particular hazard. The EN388 Mechanical Standards, tests four different hazards. Abrasion Resistance, Cut Resistance, Tear Resistance and Puncture Resistance.

- Abrasion Resistance is defined as how many cycles the glove material can handle on a course/rough surface until the glove fails.

- Cut Resistance is defined as how many cut/slicing cycles the glove can handle until the glove fails.

- Tear Resistance is defined as how much force the glove can withstand before it is compromised and torn or ripped.

- Puncture Resistance is defined as how much force the glove can withstand before the glove is pierced by a standard single point.

Usage: Gloves are commonly referred to by their cut rating alone. For example “Cut 3 glove” or “Cut 5 Glove”. The cut resistance of a level 3 glove is usually referred to as safe for handling sheet metals. Where as level 5 cut resistance is safe for handling glass and level 1 cut resistance is good for mechanic’s and general purpose.

EN374 Chemical Resistance Pictogram.

The EN374 Chemical Pictogram looks like this.

The letters below represent what chemicals are safe to use.

EN374 Chemical Pictogram, Table and Safe UsageEN374

EN374 Chemicals

| Letter | Chemical |

|---|---|

| A | Methanol |

| B | Acetone |

| C | Acetonitrile |

| D | Dichloromethane |

| E | Carbon Disulfide |

| F | Toluene |

| G | Diethylamine |

| H | Tetrahydrofurane |

| I | Ethyl Acetate |

| J | n-Heptane |

| K | Sodium Hydroxide 40% |

| L | Sulphuric Acid 96% |

If the pictogram shows the corresponding letter below the shield symbol that means the chemical has passed the test and that glove will protect you from that chemical hazard. A glove must not have a permeation breakthrough when immersed for a minimum of 30 minutes in one of the 12 chemical (shown above) to be awarded the adjacent letter.

*Permeation is defined as the process of a chemicals at a molecular level, passing through the gloves material. Some common chemicals such as; Unleaded Petrol, Methyl Ethyl Ketone, Xylene and Skydrol are not recognised by this standard. If you are using these chemicals, simply request a chemical data sheet from the manufacturer. It is important that you use the correct glove for the correct application.

Usage: If you are submerging a glove in any chemical or frequently exposing a glove to any chemical you must be sure the glove or glove’s packaging shows the EN374 pictogram symbol with the suitable letter(s) that correspond with the chemical(s) you intend on protecting your hands from.

EN374-2 Micro-Organisms Protection and Pictogram

The Micro-Organism pictogram is shown when the glove conforms to at least a performance of 60 mins (level 2) for the Penetration* test.

*Penetration is defined as chemicals and micro-organisms flowing through the porous material, seams, small holes and/or other small defects in the gloves material.

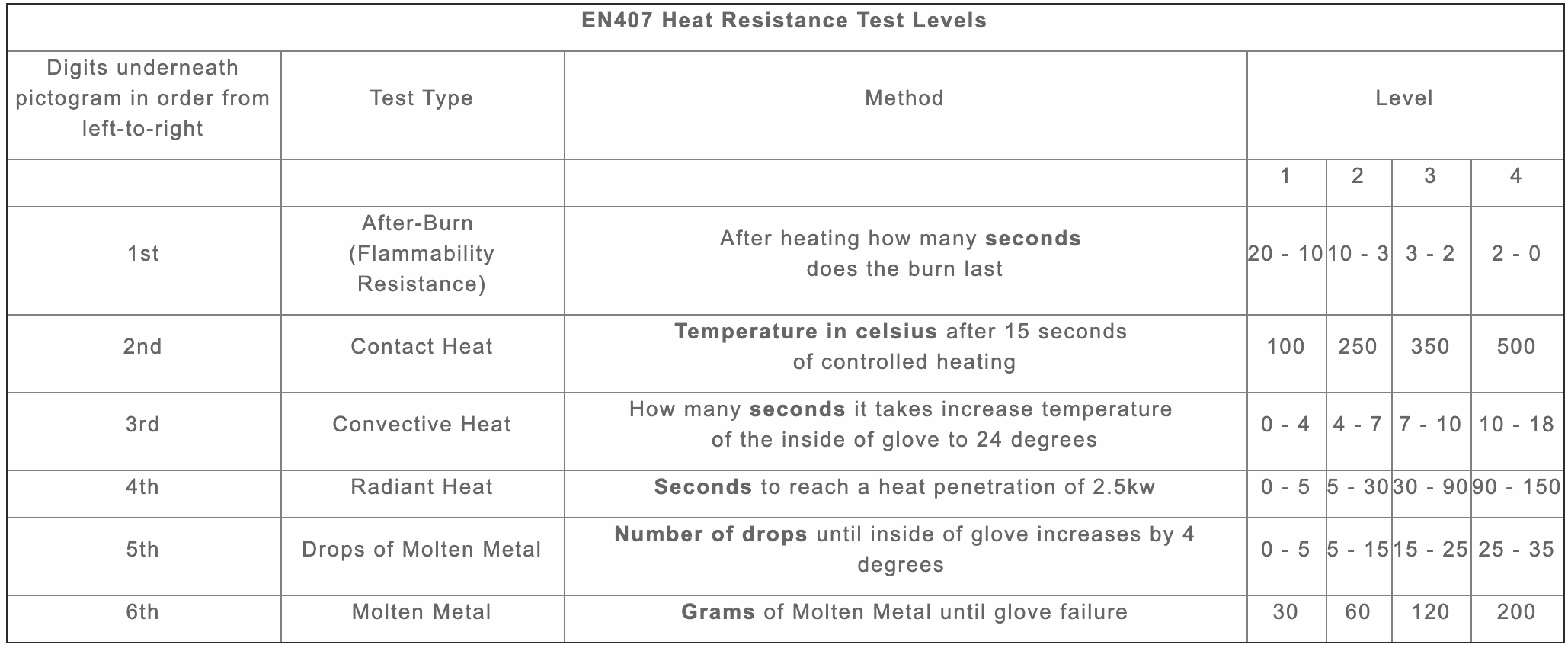

EN407 Heat Protection Pictogram

Flammability, Contact heat, Conductive Heat and Radiant Heat are all rated under this standard.

As well as Resistance to molten metal, a rating found on welding gloves.

*For more information please reach out to The Glove Company.

The Importance of Independent Testing

The Glove Company cares about your needs, that’s why we always ensure our gloves are independently tested, accredited and certified to international standards, that way we know our customers are always protected.